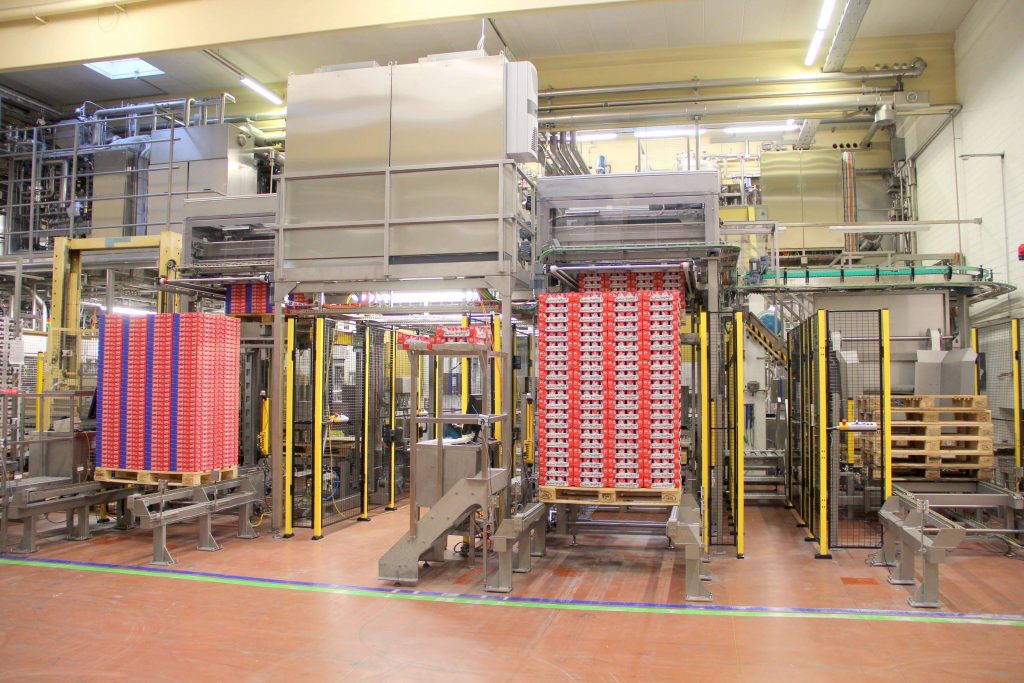

Palletizers are specifically designed to position and layer products in pre-defined formats on pallets.

Pallet unloaders disassemble individual layers on pallets.

The type and quantity of the palletized goods and pallets themselves, output requirements and the customer’s spatial constraints are used by M.A.S. to design the best possible type of palletizing equipment.

Options available include:

- layering palletizers

- portal (handling) palletizers

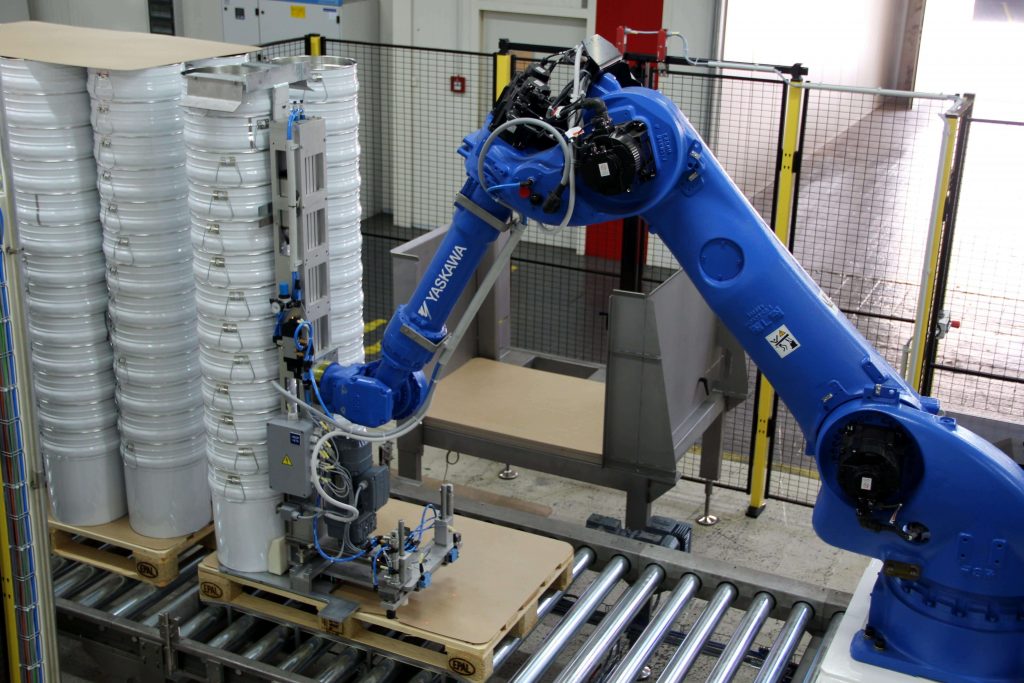

- robotic palletizers

- column palletizers

M.A.S. also offers standardised solutions:

- Palletizers for cartons and trays

- Palletizers for crates (E1, E2, E3 …)

- Palletizers for bottles, cannisters and similar containers

- Palletizers for sacks

- Palletizers for bagged products (e.g. bags of flour, sugar, salt, etc.)

- Palletizers for drums and barrels

- Palletizers for freezers (down to -30°)

M.A.S. also develops special purpose special palletizers for specific types of merchandise or specific operating conditions.

Palletizers may be equipped:

- with an integrated system to insert a separation layer between individual layers on the pallet

- automatic adjustment to different product dimensions

- remote access for troubleshooting and customer support

M.A.S. palletizers are very stable and feature a compact design with high durability and minimal maintenance requirements.

Our palletizers may be delivered in all stainless or combination steel designs to meet customer specifications.

Equipment may also be ordered with asynchronous drives or variable frequency drive controllers for servo drives.

Precision and smooth motors control the movement of the machine which combine with a rigid frame to deliver reliable operation without vibration.